Stop a Continuously Running Toilet: 5 Common Causes and Quick Fixes

A constantly running toilet is more than annoying, it’s expensive. On a standard 1.6 GPF toilet, a continuous leak can waste over 30,000 gallons in a single week. That’s money down the drain and unnecessary strain on local water systems. The good news: most causes are simple to diagnose and fix.

Flapper chain isn’t connected or adjusted.

What happens: If the chain between the handle lever and rubber flapper is disconnected or misadjusted, the flapper won’t seal properly and water keeps flowing into the bowl.

What to check:

Ensure the chain is securely attached at both ends.

Adjust slack: too short = flapper can’t seal; too long = flapper won’t lift.

If there’s a float on the chain, position it so it rests on the water surface when the flapper closes.

Quick fix: Reattach and trim the chain so there’s slight slack when the flapper is fully seated.

Handle is sticking

What happens: A stuck or jammed handle can hold the flapper open, keeping the tank in a perpetual “flush.”

What to check:

Move the handle lever up and down to free it.

Inspect the internal lever and nut for corrosion or overtightening.

Quick fix: Lubricate or adjust. If it still sticks, replace the handle/lever assembly.

Fill valve is worn or leaking

What happens: A failing fill valve lets water continue to enter the tank, even when it’s full. Sometimes you’ll see water spilling into the overflow; other times the valve leaks at the seal.

What to check:

Shut off water at the supply valve behind the toilet.

Flush to empty the tank.

Inspect the fill valve body and gasket for wear or seepage; check water level vs. overflow height.

Quick fix: Replace the fill valve and gasket if worn.

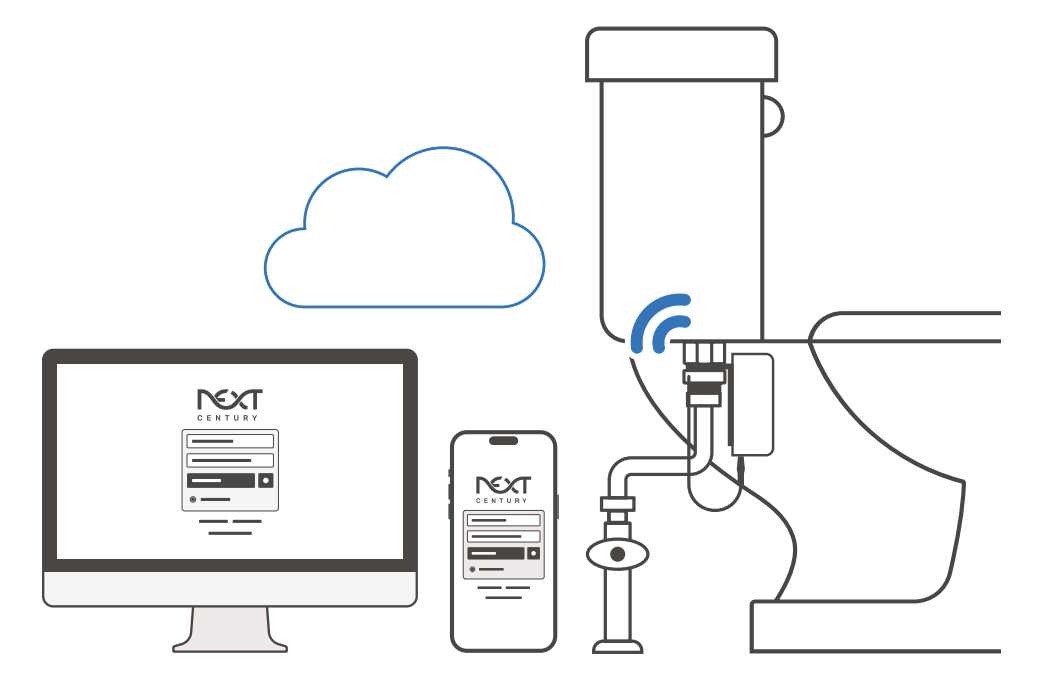

Pro move: Install the NEXT Toilet Leak Monitoring System by Integrity Meter Solutions. It detects running toilets early and alerts property teams before small leaks turn into five-figure water losses—ideal for student housing and hospitality portfolios.

Float set too high

What happens: If the float tells the valve to keep filling past the proper level, water continually runs into the overflow.

What to check:

With the lid off, observe the float height relative to the overflow tube.

Quick fix:

Use the height adjustment screw (or slide collar on newer float-cup valves) to lower the float so the final waterline sits about 1 inch below the top of the overflow tube.

Test and fine-tune until the fill stops cleanly.

Overflow tube misaligned or too tall

What happens: A misaligned or over-tall overflow tube can cause erratic flow or prevent the system from shutting off properly.

What to check:

Verify the tube is centered, intact, and sits at the correct height relative to the tank’s waterline.

Quick fix:

Realign the tube. If necessary, carefully trim it to the manufacturer’s recommended height (typically just below the tank’s fill line). Smooth any cut edges.

Conclusion: Stop the run, stop the waste. A running toilet burns cash and water, fast. Fixing chain slack, a sticky handle, float height, or a worn fill valve often solves the problem in minutes. To prevent surprise spikes and protect your budget at scale, deploy the NEXT Toilet Leak Monitoring System from Integrity Meter Solutions. You’ll get real-time leak alerts, usage insights, and peace of mind across every unit.